Welcome to :

1250 TCD Sugar Plant With Power Generation 2.5 MW In Uganda-Africa

Sugar Industry

Mill house is the cane crushing unit which consists of cane carrier, cane cutter having cutting knives, milling tandem, bagasse carrier and conveyor. Cane feeding to the cane carrier is done by unloaders and feeder table. As the cane carrier moves, the cane kicker evens out cane load in the cane carrier and then two sets of cane knives cut the cane into small pieces. This process of cane cutting is called 'cane preparation. These cane pieces then, pass through different mills and the juice is extracted. The mills are driven by D.C.motors. The residue which comes out of the mill after extraction of juice is called bagasse.

CANE HANDLING

- Cane Unloader

- Truck Tippler

- Feeder Table

- Cane Carrier

CANE PREPARATORY USES

- Cane Leveller Assembly

- Swing Knife Type Cane Chopper

- Heavy Duty Cane Shredders

- Heavy Duty Cane Fibrizer

MILL HOUSE

- Cane unloader

- Preparatory devices

- GRPF &TRPF

- Cane carrier

- Belt conveyor /Inter Rack carrier

- EOT Crane

PROCESS HOUSE

- Vacuum Pan station

- Evaporator station

- Clarification and curing station

DRIER HOUSE

- Sugar drawing , conveying , grading & bagging station

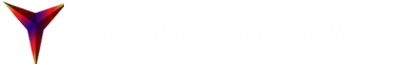

Cane Carrier

We offer a complete range of cane handling and feeding arrangements for sugar mills. Our comprehensive range of cane handling equipment includes Cane Unloader, Feeder Tables and Cane Carrier. Easy to operate, these equipment provide long service life requiring minimum maintenance. The technique of cane handling varies from region to region depending upon the type of cane availability, labour and other factors. Hence, we provide our customers with cost-effective customization of the equipment exactly as per their requirement.

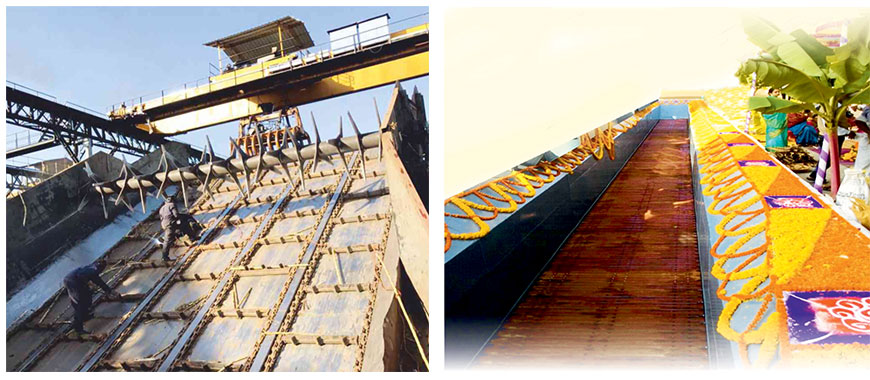

Cane Chopper & Leveller

Three Star supply Heavy Duty Cane Shredders & Cane Fibrizer specifically designed for any Sugar Cane Mill operation requirements. These are designed to achieve P.I. of 85 and above and designed for very easy installation on existing cane carriers with pocketed Anvil. We offer a complete range Cane chopper/ Cane Leveller for Sugar Mills. These are designed to achieve P.I. of 85 and above and designed for very easy installation on existing cane carriers with pocketed Anvil.

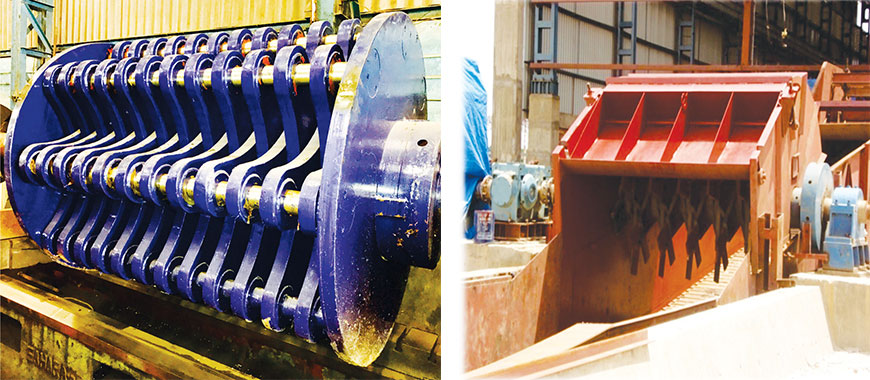

Mill House

Three Star is fully equipped to supply sugarcane milling tandem with planetary gear drive systems. Also included is the bagasse carrier and return bagasse carrier. Three Star mill machinery provides cost effective solution and bring state of art of technology, maximum efficiency giving high reliability.

Process House For Sugar Plant

Three Star is fully equipped to supply process house equipment for a wide spectrum of turn-key sugar projects State of the art sugar production technology with latest designs of equipment and systems High energy efficiency sugar plants.

Plain Tray & Multi Tray Sugar Hopper

During sugar processing, the cooling and drying of crystalized sugar is the most important step after the purification process to guarantee a high quality of finished product. Sugar drying removes excess moisture from the sugar using heat, while cooling the sugar brings it to an ideal temperature for storage and transport.